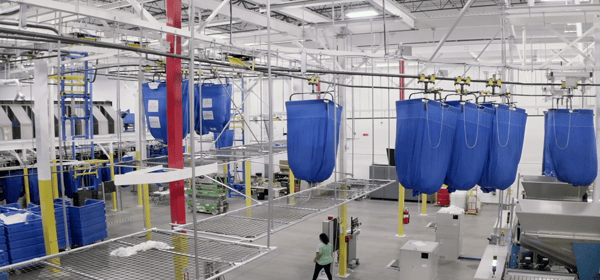

Softrol Systems offers three distinct garment sort systems: Directed Sort, Hybrid Sort, and Autosort. With a variety of features and benefits, the Directed Sort system has been proven to increase plant efficiency and improve your ability to manage work in process. Here's everything you need to know about Softrol's Directed Sort system.

What Is Directed Sort?

In basic terms, Directed Sort is an add-on software and hardware package for your existing manual garment sort system. With hand scanners, and visual or audible hanging instructions, uniform rental plants are able to analyze wearer and garment tracking data for a minimum investment.

Directed Sort Benefits And Features

Like all of Softrol Systems' solutions, the Directed Sort system comes with a variety of benefits and features that include:

- Use of existing sort rails

- Increased accuracy and speed

- Use of bar code or RFID chip

- Garment tracking data with Real-Time reporting

- Interacts with your RAS system

- Software and scanners may integrate with expansion into a Hybrid or full Autosort as throughput is increased

To advance your current manual sort system, consider Directed Sort for improved accuracy and more profit